|

|

|

|

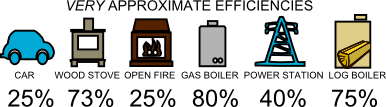

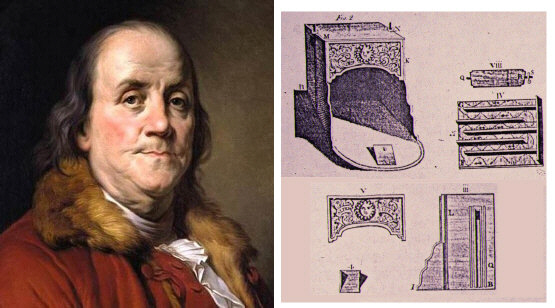

EFFICIENCY - NOT JUST A NUMBER Efficiency is a good thing, so perhaps more efficiency should be a better thing? In books like Sustainable Energy - without the hot air and in his role as Chief Scientific Advisor, David MacKay has repeatedly pointed out that efficiency is not itself a goal, it is a means to achieve what we want, and that you really do need to look at the whole picture, not just a simple headline number. Nowhere is that more true than with solid fuel heating... 'Efficiency' in heating is not, of course, how much heat is produced, it is how much heat energy is produced in proportion to how much fuel energy is put in, usually expressed as a percentage, like '80%' or '65.8%'. High efficiency is therefore a good thing, but, it is not, by any means, that simple.  MEANINGS OF EFFICIENCY 'NET' AND 'GROSS' EFFICIENCY The 'net' efficiency figure applied to solid fuel appliances tested to EN Standards doesn't account for the heat wasted in boiling off the water in the fuel. It is a bit difficult to calculate, but the more accurate 'gross' efficiency is usually about 0.91 of the the net efficiency for wood fuels and about 0.98 for mineral fuels, so a European wood-burning appliance claiming to be 80% (net) efficient is probably closer to 73% (gross). COMBUSTION EFFICIENCY AND TRANSFER EFFICIENCY There is only a certain amount of heat which can be released from fuel by burning it, roughly 7kW in each kg of coal and 5kW in each kg of dry wood. How much of that heat is actually extracted in burning is the 'Combustion Efficiency' - with many modern solid fuel appliances that can be very near to 100%. How much of that heat is then taken out of the fire and put into use in the building is the 'Transfer Efficiency', and is commonly around 70%. The actual amount of heat got out of the fuel and made useful in the building is the two efficiency types together, so an appliance with a combustion efficiency of 96% and a transfer efficiency of 80% is 0.96x0.8 = 77% Efficiency. Watch out for naughty manufacturers who quote the impressive-looking Combustion Efficiency as if it was all that mattered! APPLIANCE EFFICIENCY AND SYSTEM EFFICIENCY The efficiency number printed on the side of a stove shows how efficient it was during a particular test, that's the Appliance Efficiency. But what we really need to know is the efficiency of the whole System of stove, chimney, fuel and the building it is heating. To take a extreme, silly, example - if a 95% efficient stove had been fitted, by mistake, on the outside instead of the inside wall of the house it was supposed to heat, how efficiently would this System be heating the house? We might guess that the System Efficiency here might be just a couple of percent, the stove would be pointlessly wasting almost all its heat, yet its Appliance Efficiency would still be 95%. The System Efficiency may be very much higher or lower than the Appliance Efficiency SYSTEM EFFICIENCY MAY BE LOWER... ● Because the absolutely perfect fuel used on test isn't available. ● If the fuel is in any way damp - a slightly damp log can easily halve the appliance efficiency. ● If the appliance is burned at a very fast (=very hot) rate. ● If the appliance is burned at a very low rate so it doesn’t get hot enough to fully break-down the fuel ● If the appliance has to be operated unnecessarily fiercely simply to heat the chimney sufficiently for it to work. SYSTEM EFFICIENCY MAY BE HIGHER.... ● If heat is absorbed into a masonry chimney where it is stored and re-emitted to the building. This can account for an extra 10%, but won't be available if the chimney is outside the building, or has been lined with a metal liner separate from the masonry. ● When the appliance is operated at lower-than-usual burning rates. ● If the chimney construction results in a lower than usual gas flow rate, for instance if it is very short. LIKELY SYSTEM EFFICIENCIES It is very difficult to give any precise guidance, but a good guess, from practical experience tinged with calculated estimates suggests, that the 'real' System Efficiencies might often be something like those shown in the table below. Notice that a central heating boiler which is officially 90% efficient is likely to be less efficient in practice that one which is labelled around 77%. Notice, too, that different types of inset stove can have very different actual efficiencies, though both types look much the same and are likely to demonstrate similar efficiencies in official tests. Open fires can be surprisingly efficient, but the type in a large opening can, and often are, negatively efficient - they suck so much cool air into the building that it actually negates the heat they produce giving rise to the 'hot next to the fire, colder at the back of the room' effect. This effect was formerly used to cool the desert 'wind towers' of Arab princes, and the Houses of Parliament. (See also: Stove Performance Matrix) THE EFFICIENCY PARADOX OF STOVES Experience stove fitters will regularly have come across the circumstance where a new, more efficient, stove has replaced an older, less efficient one in an expectation of saving fuel, only to discover that the 'high efficiency' one actually uses more, often much more, fuel. How can this paradox occur? Solid fuel stoves only work because they give some heat into the chimney flue. This is necessary to keep the inside of the flue very (very) hot in order to ... ● generate the flue draught which makes the fire burn ● safely carry away poisonous waste gas, ● prevent dust and fly-ash from blocking the flue, and ● prevent damaging acidic tars from condensing inside the flue. It is trivialy simple to increase stove efficiency, you just add more heat transfer surface, but a stove with high Appliance Efficiency is, by definition, giving less heat into the chimney. When such a stove is turned down or only partly loaded it often simply won't keep the chimney hot enough to draw enough air through for combustion, and so the fire will just go out. The user soon discovers that the only way round this is to operate the stove always at a high combustion rate, with the consequent waste of fuel, even if this means (and it often does) having to open windows to get rid of the uncomfortable excess heat. Such an installation has high Appliance Efficiency but poor System Efficiency. THE BEST EFFICIENCY? Broadly speaking solid fuel stoves have a pay-off between thermal efficiency and controlability - the ones with high Appliance Efficiency generally are only so at high buring rates, try to turn them down and they often don't work at all. Appliances Efficiencies above about 85% do genuinely exist, but are likely to be highly problematical unless fitted with automatic control devices, or powered flue draught and need to be installed with special care into special-purpose chimneys and used only with very high quality, very dry, fuel. Simple appliances of supposed High Efficiency are likely to give increased fuel consumption due to the 'efficiency paradox of stoves', or be at risk of smoke, tar, rapid parts failure and dangerous fume emission. On the other hand, an Appliance Efficiency of less than about 65% is likely to be wasteful, except in circumstances where you need to give a lot of heat into the flue to make, for instance, a very short chimney work properly. Stoves in boats, for example. HOW A FAMOUS SCIENTIST GOT IT WRONG  Wood stoves look simple. They're not. Like Bertrand Russell said, they seem "something so simple as not to seem worth stating" which on investigation leads to "something so paradoxical that no one will believe it." Stoves have so far resisted all attempts to usefully describe them mathematically - unlike their gas or oil-fired competitors, or major industrial coal plant, the performance of which can be predicted on paper. We've known the actual efficiency of apparently identical stoves to vary from 17% in one case to 83% in another, with the unskilled eye being very hard-pressed to spot any difference between how they're constructed or even how they appear to burn. Benjamin Franklin thought he could increase the efficiency of wood fires by simply extracting more heat from the flue gas, he wrote at length about the simple wisdom of his brilliant idea and produced detailed plans. Fine, until someone actually built one and found that, far from giving more heat from less wood, it barely produced any heat at all, but did make huge clouds of toxic smoke. Franklin gave up on stoves. MEASURING EFFICIENCY and OUTPUT It is not normally practical to directly measure the heat output of a solid fuel appliance, instead, samples of the waste flue gas are taken - usually using a flue gas analyser the chemical composition of the gas indicates how efficiently the fuel has been burned and its temperature indicates how much of the heat generated has been captured and how much is lost into the chimney. Given the temperature of and percentage of carbon dioxide (CO2) in the exiting flue gas, the, moderately accurate, Siegert's formula gives the efficiency from: (Where A1 is: Anthracite=0.683, Coke=0.290, Bituminous Coal=0.672, Lignite=1, Peat=0.7, Dry Wood=0.650) The heat output in kW is then calculated from: ...using data on the Fuel Properties page |

|

MORE FROM Soliftec... Home ● Fuel Costs ● Installation ● Library ● About ● Air Supply ● Blogspot ● Building Rules ● Carbon Monoxide ● CE Marking ● Dictionary ● Efficiency ● Electricity - CHP ● Embodied Energy ● Fascinating Facts ● Fireplace Doctor ● Fuel Properties ● Heat Need ● Heroes ● Legislation ● Manufacturers ● Open Fires ● Ringelmann Scale ● Smog and Smoke Control ● Smoke ● Solid Fuels ● Standards ● Statistics ● Stove History ● Tables, Data and Formulas ● Test Laboratories ● Thatched Roofs ● The Carbon Cycle ● The Chimney Effect ● Wood Fuel ● Email: info@soliftec.com COPYRIGHT and ALL RIGHTS RESERVED: © BUILT WITH WHIMBERRY matrixstats |