|

|

|

|

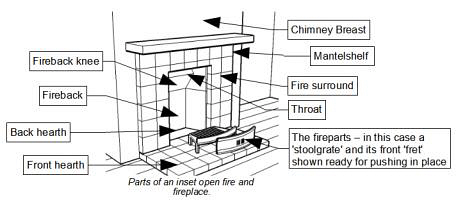

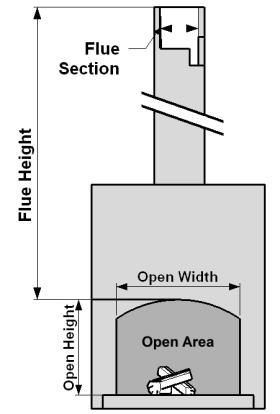

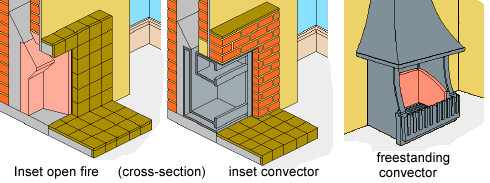

OPEN FIRES In the simplest of homes the open fire was, and in some places still is, burned in the middle of the floor, regardless of the offensive smoke. But during the 1500s in Europe the idea arose of moving the fire against the wall, and constructing a flue inside a chimney above to carry the smoke away. This general type of open fire is with us still. They tend to be both inefficient and smoky as they cannot generate temperatures high enough to fully break down the fuel. They drag huge amounts of fresh, warmed, air up the chimney which is both inefficient and can lead to the 'cold back' syndrome, where, away from the direct radiation of the glowing fire, the room is actually made cooler as vast amounts of outside air are drawn in, an effect which was actually used in the 19th Century to provide coal-fired cooling in large buildings.  Open hearth at Arnol Blackhouse Museum and early type of domestic open fire In the late 1700s the American-born Benjamin Thompson, back from pioneering research into heat in Bavaria which had earned him the title of 'Count Rumford', developed the type of improved fire which had a smaller opening (to make sure less warm air was lost up the chimney) a compact fire with ceramics around it (to created higher burring temperatures) and tapered, or 'trapezoidal' fireback to help radiate heat back into the room. From the late 19th Century, this developed into the British Standard type of fire still used in Britain and Ireland and precisely defined in BS1251  Parts of a British Standard Fireplace HOW TO MAKE AN OPEN FIRE WORK An open fire burns it draws fresh air in from the room, not just around the burning fuel, but from the whole open 'face' of the fire - the entire width and height of the fireplace opening. Without a chimney tall enough to generate The Chimney Effect with sufficient force, and a flue cross-section big enough to carry all this air away, and a sufficient amount of fresh air entering to replace it, the fire will Smoke into the room. As a general rule the area of the fireplace "face" opening must not be larger than the smallest cross-sectional area of the flue multiplied by the chimney height in metres, and there must be a permanent open air supply into the room equal to at least ½ the cross-sectional area of the flue. So;  EXAMPLE: If the flue is 5m high, and has a cross section at its smallest point of 0.3m x 0.3m (=0.09m²) then 5 x 0.09 = a maximum open area of 0.45m², and a fresh air entry into the room equal to half of 0.09m² = 0.045m² or about 200mm x 200mm. For a square opening, then the Square Root of 0.45 is 0.67, so you could have an opening 0.67m or 670mm square. If the opening is, say, 400mm (0.4m) wide then divide 0.4 onto the area 0.45 to get the permissible height of 1.1m. There is nothing you can do to a natural draught open fire to prevent it smoking other than, first giving enough air, reducing the area of the opening, or increasing the height or internal size of the the chimney.  Three methods of reducing the opening face of an open fire: from L to R; A glass reducing panel, brick infil, canopy fire  Canopy and convector casing around an open fire. Image: camelotrealfires.co.uk  |

|

MORE FROM Soliftec... Home ● Fuel Costs ● Installation ● Library ● About ● Air Supply ● Blogspot ● Building Rules ● Carbon Monoxide ● CE Marking ● Dictionary ● Efficiency ● Electricity - CHP ● Embodied Energy ● Fascinating Facts ● Fireplace Doctor ● Fuel Properties ● Heat Need ● Heroes ● Legislation ● Manufacturers ● Open Fires ● Ringelmann Scale ● Rocket Stoves ● Smoke ● Solid Fuels ● Standards ● Statistics ● Stove History ● Tables, Data and Formulas ● Test Laboratories ● Thatched Roofs ● The Carbon Cycle ● The Chimney Effect ● Wood Fuel ● Email: info@soliftec.com COPYRIGHT and ALL RIGHTS RESERVED: © BUILT WITH WHIMBERRY matrixstats |